Flow Chemistry Equipment: Flow chemistry system, pumps, flow reactor, and more

What is Flow Chemistry and How Does It Work?

Flow chemistry, also known as continuous flow processing or plug flow chemistry, represents a novel approach to chemical reactions conducted within tubes, capillaries, or microstructured devices known as flow reactors. Departing from traditional methods performed in flow chemistry equipment such as glass flasks or jacketed reactors, it involves pumping reactive components through a mixing device before passing them through a temperature-controlled flow reactor. The advantages of flow methods are the precise control over reaction parameters such as temperature, stoichiometry, and residence time. The technique lends itself perfectly to using other activation methods such as photochemistry or electrochemistry.

Flow chemistry can operate in segmented flow or continuous flow modes, catering to various applications. Continuous flow is most suited to applications where a larger amount of material is required while segmented flow is ideally suited to method development, reaction optimization, and library synthesis where smaller amounts of material are required.

Why Use Flow Chemistry?

The adoption of flow chemistry has surged across academic research groups and diverse chemical industries, including pharmaceuticals, contract research organizations (CROs), fine chemistry, materials, flavors, and fragrances. Investing in flow chemistry is an investment that will positively impact your chemistry for years to come. Transitioning to flow chemistry requires careful consideration of factors such as application diversity, scalability, desired control levels, and cost-effectiveness.

The precise control of reaction parameters as described above offers a range of benefits to the chemists, some of the benefits are described below.

Faster Reaction Optimization

Automated flow chemistry experimentation can rapidly optimize reaction conditions and evaluate novel methodology. An automated approach can screen continuous parameters such as residence time, stoichiometry, temperature and pressure. Using automated reagent injectors, chemists can explore discontinuous reaction parameters such as reagent, catalyst or enzyme screening.

Efficient serial Library Generation

Once we have optimized out conditions they can be used to either scale-up and synthesis larger amounts of material or using the same automated reagent injectors we can explore creating libraries of compounds. A flow approach to library generation can show a reduction of cost and time and is valid for fast optimization and the preparation of diverse compound series.

Reproducible reaction conditions

Flow chemistry ensures reproducibility of reaction conditions, as laminar flow mixing maintains uniform conditions throughout the process and the control of flow rates enables time and stoichiometry is constant. Automation further enhances reproducibility, ensuring consistent conditions every time.

Integration of continuous purification

Integration of continuous purification techniques streamlines reaction work-up, which is not feasible in traditional batch methods. Membrane separation, such as the Asia FLLEX allows for continuous liquid-liquid extraction and sequestering media in solid-phase reactors aid in the work-up of flow experiments.

Integration of in-line and off-line analysis

In-line and off-line analytical techniques enable real-time monitoring of reaction progression and product analysis. A single device for continuous analysis such as IR, Ramen, UV and NMR and off-line analysis with LC, MS and GC can be integrated into an automated system.

Flow Chemistry Fundamentals

Flow chemistry is all about controlling our reaction conditions. If we can do this with precision, we can harness the benefits and advantages that this synthetic technique can offer.

Whether we perform our chemistry in a batch or flow reactor we need to consider many parameters such as reaction time, reaction temperature, mixing and addition rates and molar ratios of reactants.

When we perform a flow experiment practically, we still need to consider the same reaction parameters and conditions. In a continuous flow reactor precise control of the following is made easier.

- Control addition and mixing

- Control stoichiometric equivalents

- Control reaction times

- Control reaction temperatures

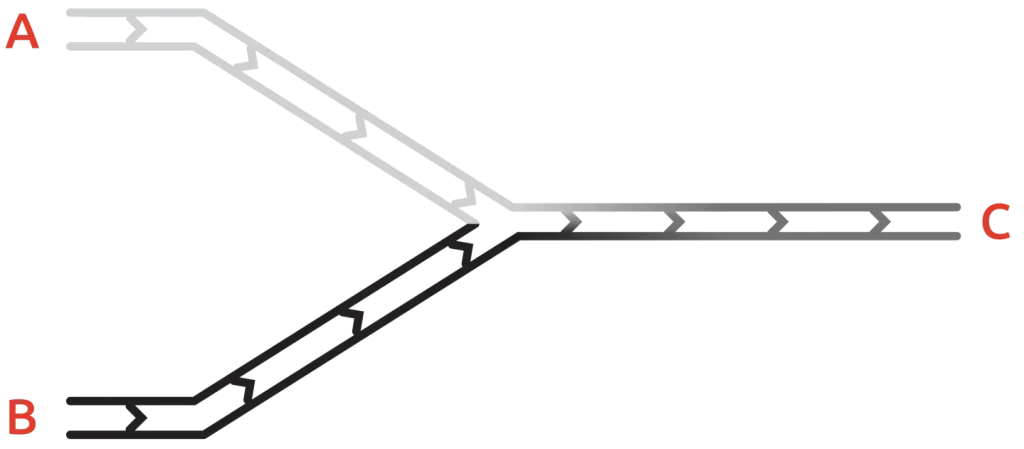

If we consider the schematic of a flow chemistry reaction as shown below we can illustrate how this is achieved.

We start with solutions A and B of our reactants of a known concentration. These are introduced into the fluidic pathway either directly through the pump (from a bottle) or via a reagent injector (if we’re introducing smaller amounts). These are pumped into our flow system and are bought together and mixed. They then travel through our continuous flow reactor and are collected.

The Modules Necessary for Flow Chemistry

The transition for chemists to translate their chemistry to suitable flow conditions requires an understanding of what equipment to use when thinking about flow chemistry processes. There are certain elements that are required to build any flow chemistry system. These can be broken down into the following subset of functions.

Pump Modules |

Precision in controlling the flow rate of reactants is critical for the success of running a flow chemistry experiment. Pumps are employed to ensure a constant and accurate flow of reagents through the system. Requirements are that they have a wide dynamic flow rate range, operate at elevated pressures, and have a high chemical compatibility. |

Flow Reactor Modules |

Flow reactors are the equivalent of a round bottom flask or jacketed reactor and come in a range of designs, including microreactors, tube reactors, and solid-phase (or packed-bed) reactors . The choice of reactor depends on the application. Tube reactors allow for longer residence times and scale-up applications while Microreactors offer better heat transfer and are applicable for faster reactions and optimization. |

Post-Reaction Modules |

Back pressure regulators allow continuous reactions under high pressure allowing above reflux temperatures and reactions that both evolve and add reactive gases. While modules that enable in-line purification and analysis can also be employed to work-up and follow reaction profiles. |

Sample Introduction and Collection Modules |

Sample introduction and collection modules enable the efficient addition of reactant and product collection. While the easiest way to introduce reactants is directly through the pump the use sample injection module allows smaller aliquots of reactants to be used saving in cost and increasing efficiency. |

Automation |

Automation further enhances productivity by enabling complex processes like method development, reaction optimization, and compound synthesis, purification, and analysis to be performed in a walk-away fashion with reproducibility of results, and time and cost savings. |

The Syrris Range of Flow Chemistry Equipment

Syrris, a leading supplier of flow chemistry equipment since 2001, offers premium flow chemistry systems like the Asia Flow Chemistry range. Designed for versatility and ease of use, Syrris systems empower researchers and industry professionals to achieve their goals efficiently.

The Syrris Asia Flow Chemistry system is an award-winning family of flow products from Syrris. Designed by chemists for chemists, it enables the widest variety of chemical reactions and ultimate ease of use. Combined with Asia Manager PC Control Software an almost unlimited combination of flow chemistry applications can be automated.

Contact our team of specialists to find out how the Syrris Asia Flow Chemistry System could help your chemistry applications.