Flow chemistry in the pharmaceutical industry

Flow chemistry, also known as continuous flow chemistry, is transforming the pharmaceutical industry by enabling more efficient, scalable, and environmentally friendly processes. This technology has revolutionized how active pharmaceutical ingredients (APIs) are developed and manufactured, providing significant advantages over traditional batch processing methods.

In this blog, we’ll explore the role of flow chemistry in the pharmaceutical industry, its applications, and the benefits it offers, particularly in API manufacturing.

How is flow chemistry used in the pharmaceutical industry?

How is flow chemistry used in the pharmaceutical industry?

Flow chemistry involves conducting chemical reactions in continuously flowing streams, rather than in traditional batch reactors. This approach offers enhanced control over reaction conditions such as temperature, pressure, and residence time, enabling more precise and reproducible chemical synthesis.

The pharmaceutical industry utilizes flow chemistry in several critical areas:

- Drug discovery: Accelerating the synthesis and optimization of new drug candidates

- API manufacturing: Enhancing the scalability, efficiency, and safety of API production processes

- Process intensification: Reducing reaction times and improving heat transfer for faster, more consistent results

- Green chemistry initiatives: Minimizing waste and energy consumption by optimizing chemical processes

Flow reactors, central to flow chemistry systems, enable the continuous introduction of reactants and the seamless removal of products, ensuring consistent reaction conditions. This technology has become a cornerstone of continuous manufacturing in the pharmaceutical sector.

What are Active Pharmaceutical Ingredients (APIs)?

APIs are the biologically active components in pharmaceutical drugs that produce the desired therapeutic effect. For example, paracetamol is the API in pain-relief tablets. APIs are often combined with inactive ingredients (excipients) to create the final drug formulation.

The complexity of API molecules requires precise and reliable chemical synthesis methods. Flow chemistry is ideally suited for producing APIs, offering enhanced control and efficiency compared to traditional batch methods.

What is API manufacturing?

API manufacturing is the process of synthesizing the active components of a pharmaceutical drug. This involves complex chemical synthesis techniques, often requiring multiple steps, stringent quality control, and compliance with regulatory standards.

Traditional batch processes have long dominated API manufacturing but come with challenges such as:

- Long reaction times: Slower processing and higher energy consumption

- Variability: Greater risk of batch-to-batch inconsistencies

- Safety concerns: Handling hazardous materials in large quantities increases the potential for accidents

- Environmental impact: Higher waste generation and resource usage

Continuous flow chemistry has emerged as a solution to these challenges, enabling a shift towards more efficient, safer, and sustainable API manufacturing processes.

Flow chemistry in API manufacturing

Flow chemistry offers numerous advantages in API manufacturing, making it a preferred choice for leading pharmaceutical companies due to its efficient use of reagents.

Here’s how flow chemistry improves API production:

- Enhanced reaction control:

-

- Precise control over temperature, pressure, and residence time allows for optimized reaction conditions

- Improved selectivity and yield, reducing the formation of unwanted by-products

-

- Scalability:

-

- Continuous flow systems can be easily scaled up from laboratory to production levels

- Consistent reaction conditions ensure seamless scaling without extensive re-optimization

-

- Safety:

- Smaller reactor volumes reduce the risk associated with hazardous reactions

- Improved heat transfer minimizes the likelihood of thermal runaways

- Green chemistry:

- Reduced waste and energy consumption align with sustainability goals

- Compatible with renewable feedstocks and environmentally friendly solvents

- Shorter development times:

- Faster process optimization and reduced start-up times accelerate time-to-market for new drugs

Continuous-flow synthesis has proven particularly valuable in producing complex APIs and natural products, streamlining processes that would otherwise be challenging or inefficient in batch systems.

Benefits of Flow Chemistry in the Pharmaceutical Industry

The adoption of flow chemistry in the pharmaceutical industry offers several benefits, including:

1. Efficiency and speed

Flow chemistry enables continuous processing, significantly reducing reaction times compared to batch methods. Faster reaction kinetics, enhanced heat transfer, and consistent flow rates in flow reactions contribute to higher throughput and productivity.

2. Precision and reproducibility

With advanced control over reaction parameters, flow chemistry ensures high precision and consistency. This is crucial for maintaining compliance with regulatory standards and delivering high-quality pharmaceutical products.

3. Scalability

Flow chemistry systems can be easily scaled to meet production demands, whether for small-scale laboratory studies or large-scale manufacturing. Continuous flow processes eliminate the need for costly and time-consuming batch revalidation.

4. Safety and compliance

Reduced reactor volumes and automated systems enhance safety by minimizing exposure to hazardous materials. Flow chemistry also facilitates adherence to Good Manufacturing Practice (GMP) guidelines, ensuring compliance with regulatory requirements.

5. Sustainability

By optimizing resource utilization and minimizing waste, flow chemistry supports green chemistry initiatives. Lower solvent usage, energy efficiency, and reduced emissions make it a sustainable choice for the pharmaceutical industry.

6. Versatility

Flow reactors are compatible with a wide range of chemistries, including those involving high pressures, high temperatures, or unstable intermediates. This versatility makes them suitable for diverse applications, from drug discovery to commercial manufacturing.

Reliable flow chemistry equipment with Syrris

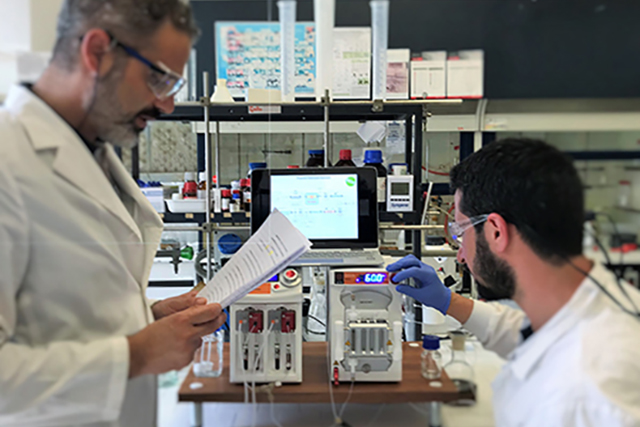

At Syrris, we specialize in cutting-edge flow chemistry solutions designed to meet the unique needs of the pharmaceutical industry. Our range of flow systems and supporting modules empowers researchers and manufacturers to harness the full potential of continuous flow technology.

Key products and features:

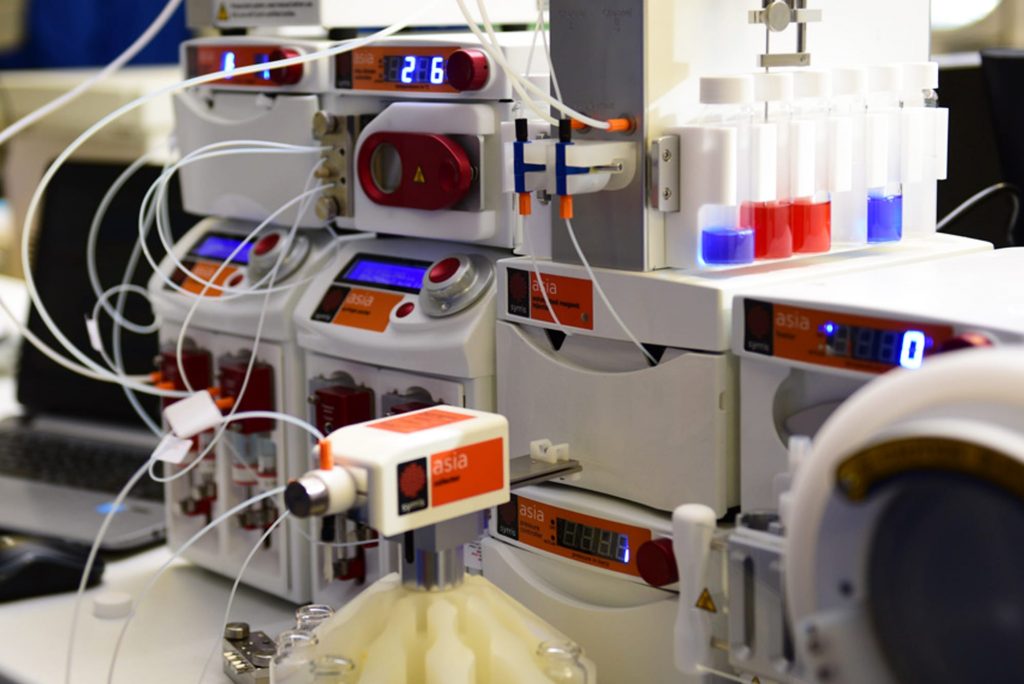

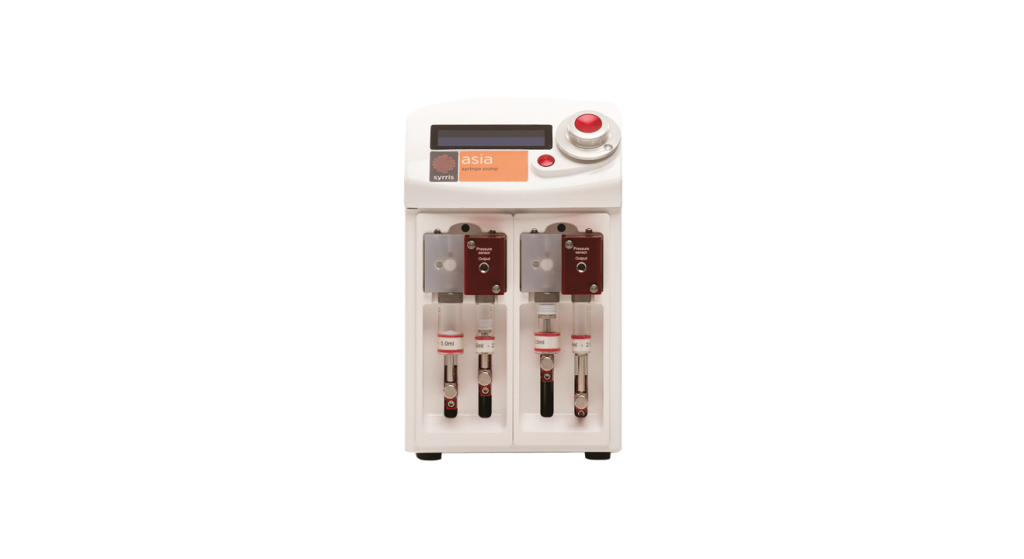

- Asia Flow Chemistry System:

- A modular and flexible platform for continuous-flow synthesis

- Advanced features for temperature and pressure control, ensuring precise and reproducible results

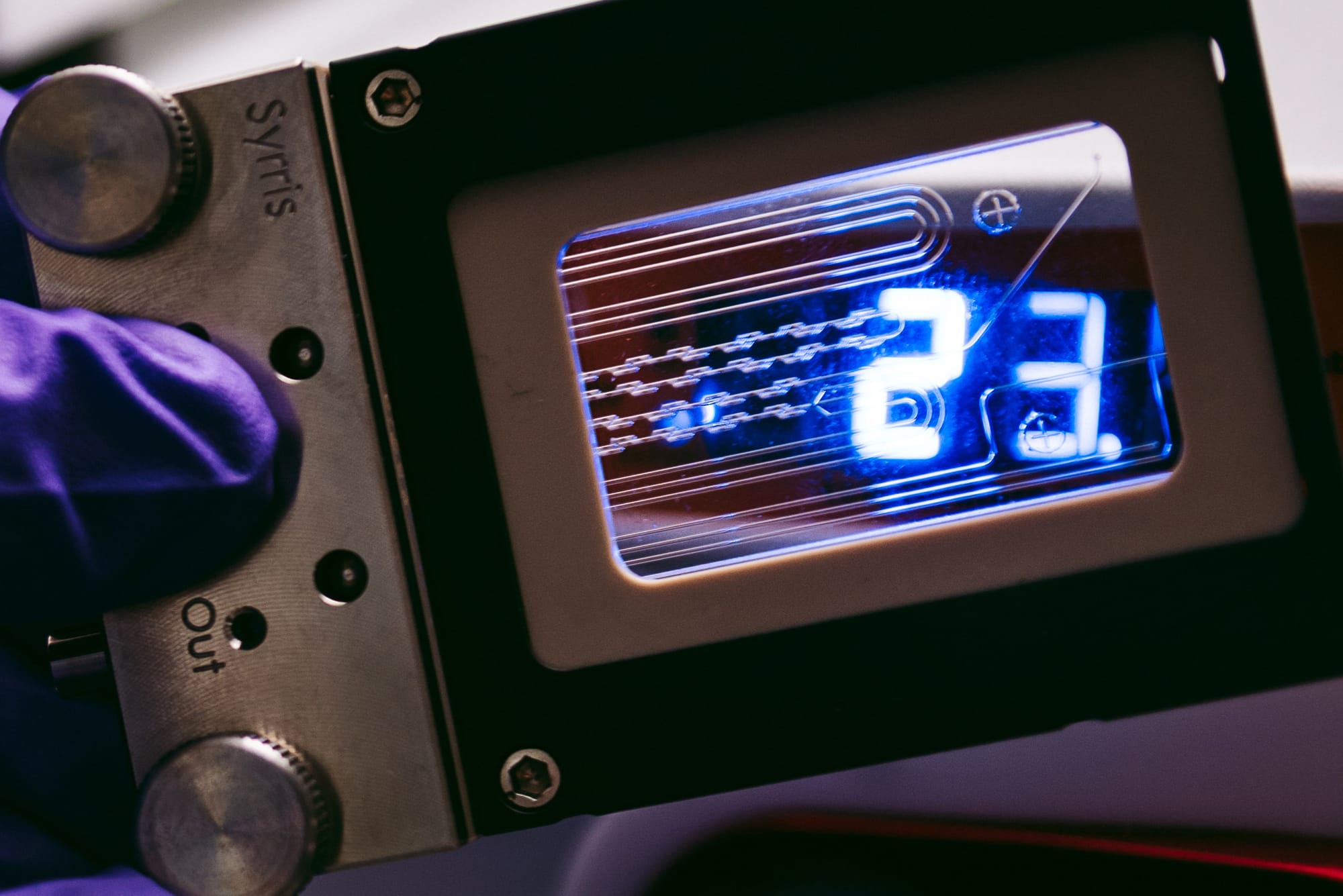

- Syringe pumps:

- High-precision pumps for accurate flow rate control

- Ideal for both low and high flow rate applications, supporting continuous processes with minimal variability

- Customizable solutions:

- Tailored systems to meet specific customer requirements

- Scalable designs suitable for both R&D and large-scale production

Our technology is backed by extensive service details and support, ensuring smooth implementation and operation in any laboratory or production environment. With Syrris, you gain access to innovative products, expert advice, and a commitment to excellence.

Ready to transform your pharmaceutical processes?

Syrris is your trusted partner in advancing flow chemistry in the pharmaceutical industry. From drug discovery to API manufacturing, our continuous flow solutions deliver unparalleled precision, efficiency, and scalability. Whether you’re exploring new chemical synthesis routes or optimizing existing processes, Syrris provides the tools and expertise to help you succeed. Explore our full range of flow chemistry products here.

Contact us today to learn more or request a quote. Our team of experts is ready to assist you in finding the right solution to revolutionize your pharmaceutical workflows with Syrris.

Contact our team of specialists to find out more about our flow chemistry products and how they can benefit your chemistry.

Syrris products featured in this article

Asia Flow Chemistry System

Asia Syringe Pump

Atlas Syringe Pump

Atlas Syringe Pump XL

What we say

“The most rewarding part of my role is when I visit laboratories around the world and see how our technology is being used by researchers to perform cutting-edge science.”