Green Chemistry: A Sustainable Approach in the Pharmaceutical Industry

In recent decades, the global push towards sustainability has led to the widespread adoption of green agendas across various industries. This proactive approach prioritizes environmentally-friendly practices, aiming to mitigate the adverse impacts of human activities on the planet. Within this framework, Green Chemistry in the pharmaceutical industry emerges as a fundamental pillar, advocating for the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. Such principles resonate profoundly within the chemical and pharmaceutical sciences, where the quest for innovation intersects with a responsibility for ecological stewardship.

What is Green Chemistry?

Green Chemistry, initially developed by Paul Anastas and John Warner in the late 1990s1, advocates for the design of chemical products and processes that minimize environmental impact. At its core, Green or Sustainable Chemistry seeks to promote sustainability by encouraging the development of safer, more efficient, and less wasteful practices across the chemical industry.

Anastas and Warner outlined 12 principles that serve as guiding lines for the implementation of Sustainable Chemistry. These principles encompass a spectrum of considerations, ranging from the primordial prevention of waste generation and the design of safer chemicals to the use of renewable feedstocks, encouraging the use of catalysis and the pursuit of energy efficiency. By adhering to these principles, chemists strive to mitigate the generation of hazardous substances, minimize resource depletion, and reduce the ecological footprint of chemical processes.

The 12 principles of Green Chemistry are deeply linked with the 12 principles of Green Engineering3, forging a synergistic relationship between these complementary disciplines. Green Engineering extends the principles of sustainability beyond chemistry to encompass engineering practices, emphasizing the importance of incorporating environmental considerations into the state-of-art of engineering solutions. Both frameworks share common goals of minimizing environmental impact, optimizing resource utilization, and fostering innovation towards a more sustainable future.

Flow Chemistry and Green Chemistry in Pharma Industry

Flow chemistry and continuous processing shares common ground towards the fulfilment of some principles of Green Chemistry within the pharma industry. These methodologies offer efficient, sustainable alternatives to traditional batch processes, aligning with the goals of waste reduction, energy efficiency, and safer chemical processing.2,4

When compared to batch-wise techniques, flow techniques enables more precise control over reaction conditions, generally, leading to faster and safer reactions, higher selectivities and higher yields with a reduced waste generation, you should consider What are the benefits of flow chemistry in reducing the environmental impact of drug synthesis? By continuously pumping reagents through a reactor, flow chemistry minimizes the need for excess solvents and reagents, resulting in more streamlined processes and reduced environmental impact. The high ratio surface-area/volume of the flow reactors allows efficient heat transfer minimizing the energy consumption and enhancing productivity. With better control of chemical parameters, flow chemistry also facilitates the use of hazardous reagents opening access to the “forbidden chemistry”, enhancing safety while maintaining efficiency.5

The implementation of in-line process analytical technologies (PAT) enables real-time process monitoring, any deviation in the process can be addressed instantly, which has direct positive impact on the product quality.2 Continuous processing extends the benefits of flow chemistry by integrating multiple reaction steps into a single continuous operation. This eliminates the need for intermediate isolation and purification steps, further reducing waste and energy consumption.7

Flow chemistry can be combined with photochemistry or electrochemistry opening the possibility to use chemical reactions promoted by light or electrons, in perfect alignment with the green principle of atom economy, and optimizing resource utilization.

Moreover, the implementation of flow chemistry and continuous processing into manufacturing chemical products contributes to overall process intensification, where smaller equipment footprints, leads to reduced energy consumption and lower operating costs. This not only enhances the economic viability of pharmaceutical manufacturing but also reinforces the industry’s commitment to sustainability and environmental consciousness.

Sustainability Metrics in Green Chemistry

In conjunction with the 12 Principles of Green Chemistry and Green Engineering, there are multiple metrics available for evaluating the environmental sustainability of a process, particularly in the context of pharma companies. One commonly used metric is the E-factor, as defined by Sheldon8, which measures the mass ratio of waste to desired product (Equation 1). While the bulk chemical industry (e.g. petrochemical industry) generally maintains E-factors <1, the pharmaceutical sector often operates with E-factors between 25 and 200.9 Low product yields, excess reagents, multi-step sequences and solvent use for purification are all contributions to an increase in E-factor.

Equation 1 – E-Factor

In recent years, a new measure known as process mass intensity (PMI or MI) has emerged. PMI calculates the ratio between the total mass of materials used and the mass of the final product and is an attempt to focus attention on the inefficiency associated with a typical process10 (Equation 2).

Equation 2 – Process mass intensity (PMI)

Another important metric is atom economy or atom efficiency, which is determined by the ratio of the molecular weight of the product to the sum of the molecular weights of all substances formed in the stoichiometric equation for the reaction. In contrast, the Life Cycle Assessment (LCA) takes a more holistic approach to sustainability by considering all environmental impacts associated with every stage of a product’s life, starting from the acquisition of raw materials.10

Examples of using Green Chemistry

Gases like CO, H2, and O2 are typically low-cost, easily eliminated at the end of a process, and, above all, their use allows for a more straightforward and environmentally friendly path to the desired product, thereby following the Green Principles of maximizing mass efficiency and minimizing waste. Whitin a continuous process, gases can be precisely dosed and mixed efficiently with the liquid stream, ensuring a safe and reliable execution of multiphase reactions.2

Safety dealing with compressed gases was the main driver for Eli Lilly to develop continuous processes employing H2 at high pressure (50-70 bar) for the syntheses toward the API evacetrapib on a 2 metric ton scale11 (Scheme 1). The flow processes were rated as low-risk compared to high-risk batch processes since the reactor volumes were smaller and run >98% liquid filled.2

Biocatalysts, or enzymes, are indispensable tools for the chemical synthesis of complex achiral and chiral compounds in a highly selective manner. The use of continuous flow in biotransformations provides several advantages, such as reduced enzyme inhibition by removing substrates and products, as well as simplified downstream processing through the use of immobilized catalysts. By implementing an efficient flow system for a chemo-enzymatic Baeyer−Villiger oxidation, high yields of the product per reactor capacity were achieved, eliminating the need to handle unstable peracids.12 This process involved the presence of Candida antarctica lipase B (CALB) immobilized on multiwalled carbon nanotubes through physical adsorption (Scheme 2).

The nanocatalyst generated peracid in situ using ethyl acetate and 30 wt % aq. hydrogen peroxide as the primary oxidant. Remarkably, a high product yield of 87% and selectivity exceeding 99% were attained for the Baeyer−Villiger oxidation of 2-methylcyclohexanone to 6-methyl-ε-caprolactone within 8 hours at 40 °C. The use of ethyl acetate as both the solvent and peracid precursor is an environmentally favorable choice. This study represents the first application of a nanobiocatalyst for chemoenzymatic transformation, offering process improvements in terms of increased yield compared to the batch process and a shorter reaction time under mild conditions.

Staying Ahead of the Green and Sustainable Chemistry Curve

Staying ahead of the curve in Green Chemistry within the pharmaceutical industry requires a proactive approach that integrates sustainable practices at every stage, from early discovery to API (Active Pharmaceutical Ingredient) manufacturing.

In early discovery, medicinal chemists can prioritize the design of molecules that exhibit favourable green chemistry characteristics by adopting green practices. This includes selecting renewable starting materials, minimizing the use of hazardous solvents and reagents, and designing molecules with higher atom economy and biodegradability. Computational tools can aid in predicting the environmental impact of candidate molecules, allowing for informed decision-making during the drug design process.2,6

Parallel to this, in API manufacturing, process chemists can explore green chemistry techniques such as flow chemistry, continuous processing, and catalysis. These methodologies enable more efficient and sustainable synthetic drug development, reducing waste generation, energy consumption, and solvent usage, thereby having a positive impact on the environment.

Embracing green chemistry principles in API manufacturing also involves optimizing reaction conditions, maximizing the use of renewable feedstocks, and implementing robust recycling and waste management strategies.6

Enable Green Innovation with Syrris

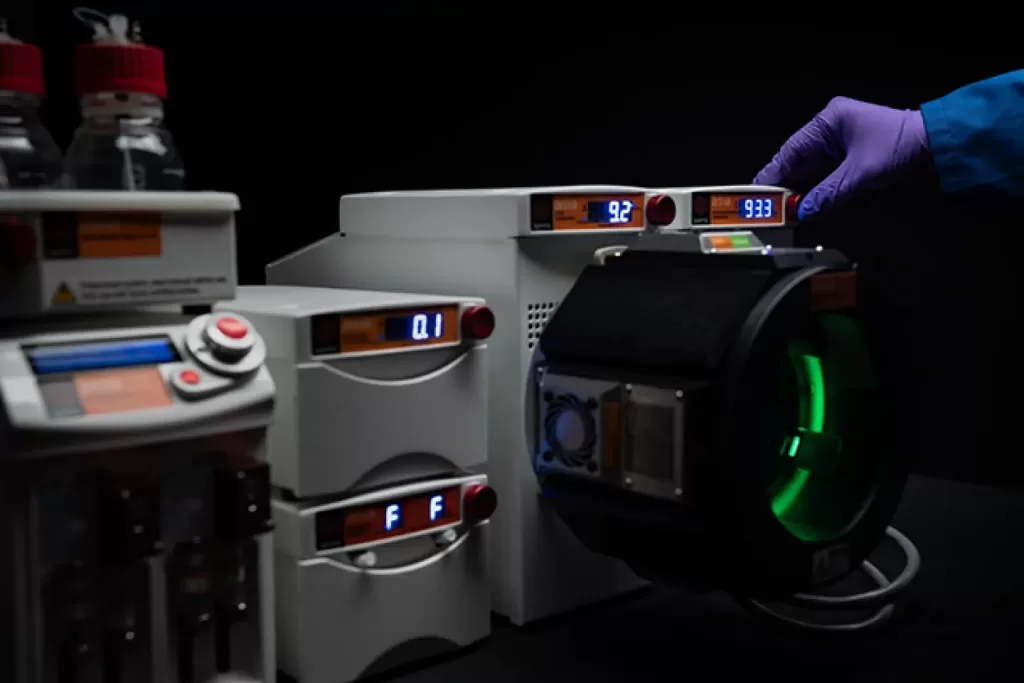

Syrris, a leading provider of flow chemistry solutions, offers innovative products that empower researchers to advance their green chemistry agendas.

Sustainable Drug Discovery and Green Chemistry

Through their cutting-edge flow equipment and automated systems Syrris equips customers with the tools to optimize chemical processes, reduce waste, and enhance sustainability in their research endeavours.

With the Asia Automated Reactor Injector, Syrris empowers researchers to expedite optimization processes and explore a broader chemical space with unparalleled efficiency while implementing green chemistry practices. This advanced tool allows for rapid screening of reaction conditions, also is the perfect equipment to enable the easy generation of libraries of compounds (link with brief page Using Automated Flow Chemistry in Compound Library Generation). Using the groundbreaking control software Asia Manager, users can program the Asia System to even explore discontinuous reaction parameters such as reagent, catalyst or enzyme screening. Syrris’ Automated Reactor Injector allied with Asia Syringe Pump and Automated Collector not only accelerates drug discovery efforts but also minimizes resource consumption and waste generation.

Green Manufacturing

Syrris Asia System can address laboratory scales and rapid and efficient screening. In case of higher scales of production are required, Chemtrix, a sister company under the AGI Group umbrella, has cutting-edge solutions and a range of small-footprint Flow Reactors for mg-scale reaction screening, through to multi-tonne industrial production in continuous processing technologies. The company is uniquely positioned to drive the transition towards greener and more sustainable manufacturing practices.

The Future of A Sustainable Pharmaceutical Industry

The American Chemical Society Green Chemistry Institute (ACS GCI) has sought to be the premier change agent that has the knowledge, expertise, and capabilities to catalyse the movement of the chemical enterprise toward sustainability through the application of green chemistry principles. To fulfil its mission, ACS GCI supports research, works to integrate green synthesis into all levels of chemical education, aids companies with industrial implementation, hosts conferences, and coordinates efforts with an international network of green chemistry advocates.10 The future of Green Chemistry holds immense promise, especially within the pharmaceutical industry, where sustainability and innovation are increasingly intertwined. As environmental concerns continue to drive regulatory agencies and consumer demands, pharmaceutical companies are compelled to adopt greener practices. Green Chemistry offers a pathway to meet these expectations by fostering the development of safer, more efficient, and environmentally friendly processes for drug synthesis and production.

In the coming years, one can anticipate a growing emphasis on the integration of Green Chemistry principles into pharmaceutical R&D and manufacturing. This shift will not only reduce the environmental footprint of drug production but also improve cost-efficiency and regulatory compliance. Pharmaceutical companies’ adoption of Green Chemistry will likely experience benefits such as reduced waste generation, lower energy consumption, and enhanced reputation as environmentally responsible entities.

References

1 P. T. Anastas and J. C. Warner, Green Chemistry: Theory and Practice, Oxford University Press, New York, 1998.

2 D. Dallinger and C. O. Kappe, Why flow means green – Evaluating the merits of continuous processing in the context of sustainability, Curr. Opin. Green Sustain. Chem., 2017, 7, 6–12.

3 P. T. Anastas and J. B. Zimmerman, Design Through the 12 Principles of Green Engineering, IEEE Eng. Manag. Rev., 2007, 35, 16–16.

4 J. A. Bennett, Z. S. Campbell and M. Abolhasani, Role of continuous flow processes in green manufacturing of pharmaceuticals and specialty chemicals, Curr. Opin. Chem. Eng., 2019, 26, 9–19.

5 M. B. Plutschack, B. Pieber, K. Gilmore and P. H. Seeberger, The Hitchhiker’s Guide to Flow Chemistry, Chem. Rev., 2017, 117, 11796–11893.

6 M. Baumann, T. S. Moody, M. Smyth and S. Wharry, A Perspective on Continuous Flow Chemistry in the Pharmaceutical Industry, Org. Process Res. Dev., 2020, 24, 1802–1813.

7 S. Newton, C. F. Carter, C. M. Pearson, L. de C. Alves, H. Lange, P. Thansandote and S. V. Ley, Accelerating Spirocyclic Polyketide Synthesis using Flow Chemistry, Angew. Chemie Int. Ed., 2014, 53, 4915–4920.

8 R. A. Sheldon, The E Factor: fifteen years on, Green Chem., 2007, 9, 1273.

9 R. Ciriminna and M. Pagliaro, Green Chemistry in the Fine Chemicals and Pharmaceutical Industries, Org. Process Res. Dev., 2013, 17, 1479–1484.

10 P. T. Anastas, Handbook of Green Chemistry, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany, 2018, vol. 11- Green.

11 S. A. May, M. D. Johnson, J. Y. Buser, A. N. Campbell, S. A. Frank, B. D. Haeberle, P. C. Hoffman, G. R. Lambertus, A. D. McFarland, E. D. Moher, T. D. White, D. D. Hurley, A. P. Corrigan, O. Gowran, N. G. Kerrigan, M. G. Kissane, R. R. Lynch, P. Sheehan, R. D. Spencer, S. R. Pulley and J. R. Stout, Development and Manufacturing GMP Scale-Up of a Continuous Ir-Catalyzed Homogeneous Reductive Amination Reaction, Org. Process Res. Dev., 2016, 20, 1870–1898.

12 M. P. Thompson, I. Peñafiel, S. C. Cosgrove and N. J. Turner, Biocatalysis Using Immobilized Enzymes in Continuous Flow for the Synthesis of Fine Chemicals, Org. Process Res. Dev., 2019, 23, 9–18.

How Can Syrris Support Sustainable Pharmaceutical Manufacturing?

The Syrris Asia Flow Chemistry system is at the forefront of this application. The fully automated flow platform allows for method development to establish the optimum conditions for continuous synthesis routes that can be transferred to the automated synthesis of hundreds of exploratory compounds. Using the same system any “hit” or “lead” compound can readily be scaled to the gram or even kilogram amount.

For chemists wanting the greatest range of functionality and flow chemistry equipment available the Asia Premium Flow Chemistry System is the perfect match.

Contact our team of specialists to find out how the Syrris Asia Flow Chemistry System could help your chemistry applications.