Jacketed Glass Reactor for Advanced Temperature Control

A jacketed glass reactor is an essential tool in chemical processing, known for its precise control over reaction conditions.

As a leader in chemical processing solutions, Syrris provides a wide range of cutting-edge jacketed glass reactors designed to meet the diverse needs of laboratories and production environments.

Our reactors offer automation, superior temperature control, durability, and flexibility, ensuring efficient and safe chemical reactions.

Jacketed glass reactor vessels for precision chemical processes

A jacketed glass reactor is a specialized type of reaction vessel that allows for the control of temperature during chemical processes, often equipped with a condenser. This is achieved through an outer jacket surrounding the inner vessel, where heat or cooling fluid can be circulated.

Whether you’re working on synthetic reactions, crystallization, or process scale-up, Syrris’ jacketed reactors are designed to provide consistent, reliable, and precise control over a wide temperature range, making them ideal for a diverse range of laboratory and industrial applications, including reaction optimization, pilot production, process development, and research.

From maintaining high precision during temperature-sensitive reactions to facilitating rapid scale-up, our products stand out for their robustness and adaptability.

Features and benefits of Syrris jacketed reactors

Our jacketed glass reactors are engineered with quality and versatility in mind, making them suitable for both small-scale lab experiments and large-scale production processes. Here are some of their key features and benefits:

| Precise temperature control | The outer jacket enables efficient heating and cooling, allowing precise control over the reaction temperature. This is critical for maintaining reaction stability and ensuring accurate results. |

| Durability and chemical resistance | Made from borosilicate glass and stainless steel, our reactors are resistant to heat, cold, and a wide range of chemicals, providing excellent longevity and safety during complex processes. |

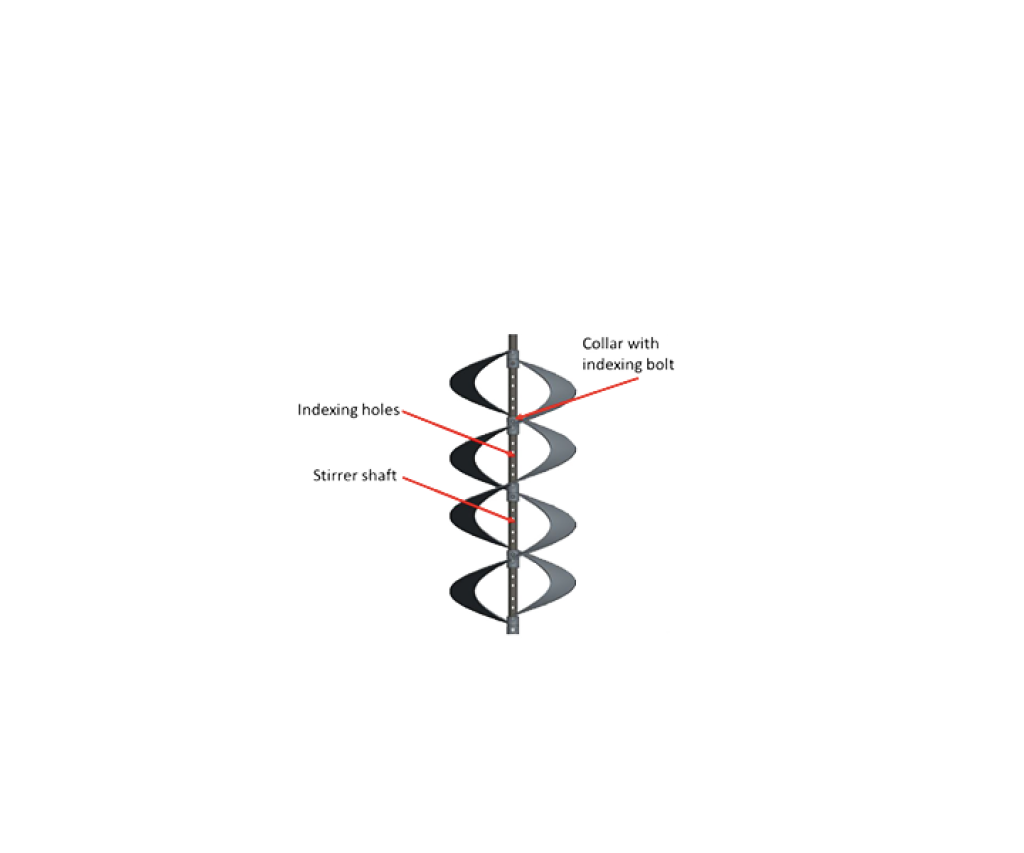

| Ease of use | Our reactors feature PTFE stirrers, easy-to-use flange ports, and intuitive control systems for seamless operation. |

| Versatile applications | Suitable for a variety of synthetic reactions, crystallization, and vacuum environment processes. They can be used as standalone units or in. |

These important features make Syrris jacketed reactors a reliable choice for scientists and engineers seeking precision, flexibility, and safety in their chemical processes.

Innovative design and construction of our jacketed glass reactors

At Syrris, we believe that the quality of the materials used in the construction of our equipment defines its performance. Our jacketed glass reactors are designed to provide optimal performance under various conditions, thanks to our careful selection of materials and innovative design.

Materials used

The inner vessel of our jacketed reactors is constructed from high-quality borosilicate glass, known for its excellent thermal and chemical resistance. This material ensures that the reactors can withstand high temperatures, aggressive chemicals, and rapid temperature changes without compromising the integrity of the vessel. The outer jacket, made from high-quality stainless steel, enhances durability and ensures consistent thermal transfer, making it ideal for glass chemical reactors.

We also offer options with non-jacketed glass reactors, which are suitable for specific applications that do not require active temperature control. Our products are engineered to meet sanitary grade standards, ensuring safety and cleanliness in every process.

Applications of Syrris jacketed glass vessels

Syrris’ glass jacketed reactors are used in a wide range of applications across various industries:

- Process development: Ideal for optimizing reaction conditions, scaling up reactions, and performing detailed process studies, including distillation processes.

- Pharmaceutical research: Supports synthesis, crystallization, and reaction optimization, offering the precision needed for high-purity compound development.

- Chemical production: From small-scale synthesis to large-scale chemical production, our reactors facilitate efficient and controlled production environments.

- Material science: Perfect for the development of new materials, composites, and polymers.

Whether for educational labs, research institutions, or industrial production, our jacketed glass reactors deliver reliable performance across a wide range of applications.

Customization options for jacketed glass reactors

Syrris understands that every chemical process has unique requirements. That’s why we offer extensive customization options for our jacketed glass reactors, including:

- Size and volume: Choose from a variety of volumes, from small laboratory-scale reactors to larger vessels suitable for industrial-scale applications.

- Temperature range: Configure your system to suit your desired temperature control range, from deep cooling to high-temperature heating.

- Port options: Custom flange ports can be added for additional sensors, stirrers, or other equipment, enhancing the versatility of the reactor.

- Material variants: Select from different materials like PTFE-coated components, stainless steel, or high borosilicate glass to suit specific chemical processes.

These custom options allow users to tailor their equipment to their exact needs, ensuring efficiency, safety, and ease of maintenance.

Why choose jacketed glass reactors from Syrris?

Syrris has been at the forefront of developing innovative chemical processing solutions, delivering reliable lab equipment with a focus on quality, safety, performance, and advanced insulation materials. Our jacketed glass reactors are a testament to this commitment. Here are just a few reasons why Syrris is the preferred choice for laboratories and industrial applications worldwide:

- High-quality materials: We use high-quality borosilicate glass and stainless steel for all our products, ensuring durability and safety across different applications.

- Advanced temperature control: Our systems are designed to handle a wide range of temperatures, featuring advanced thermal insulation for consistent and precise thermal management.

- Customization: From lab scale to pilot process needs, our reactors can be tailored to meet the requirements of different chemical reactions, ensuring flexibility and functionality.

- Ease of maintenance: Our reactors are designed for easy disassembly and cleaning, reducing downtime and ensuring that your lab runs smoothly.

- Global support and service: With a network of support around the world, Syrris is committed to providing excellent service and technical assistance for all our products.

Ready to enhance your chemical processes?

Syrris jacketed glass reactors are designed to streamline your laboratory and production processes, offering robust and reliable performance across different types of chemical reactions. Whether you are scaling up from lab to production or optimizing your processes, Syrris provides the solutions and support you need.

Contact us today to learn more about our jacketed glass reactors and how they can benefit your chemical applications.

Syrris’ reputation for excellence and innovation has made it a trusted partner in the chemical processing industry, with chemists choosing our jacketed glass reactors to deliver precision, flexibility, and safety in their chemical processes.

Contact our team of specialists to find out more about Syrris’ jacketed glass reactors and how they can benefit your chemical applications.

Syrris products featured in this article

Atlas HD Automated Jacketed Reactor

Orb Jacketed Reactor

Orb Pilot Scale-up Reactor

Custom Reactor Systems and Pressure Reactor Systems

What we say

“The most rewarding part of my role is when I visit laboratories around the world and see how our technology is being used by researchers to perform cutting-edge science.”