There is a range of Atlas Software products designed for the control of experiments, data collection, and data analysis.

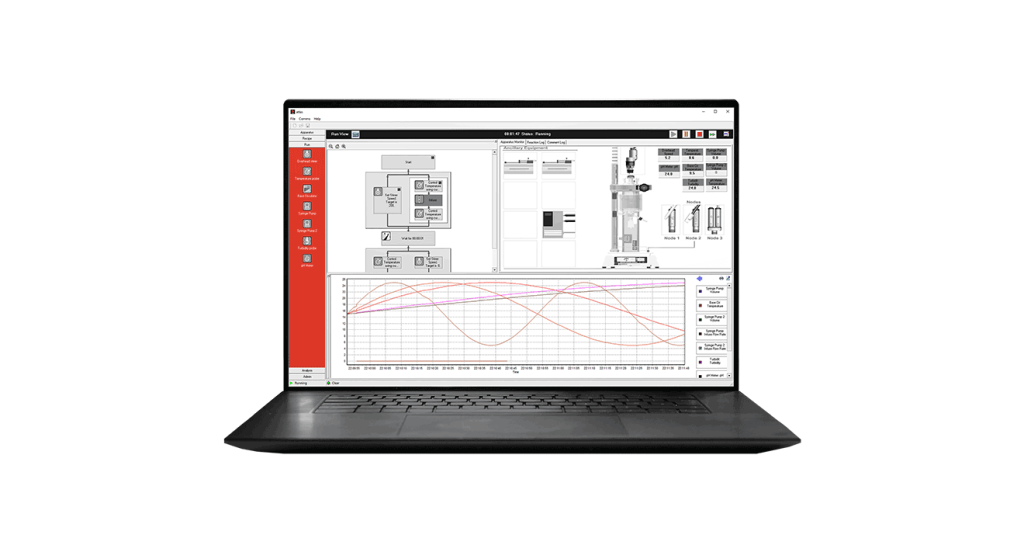

The laboratory software used to control Atlas apparatus (and other manufacturers’ apparatus) is called Atlas PC Software 1.

A summary of the Atlas reactor software range is below;

- Atlas PC Software 1: For whole system control, configuration and analysis of Atlas hardware and all RS232 controlled devices such as pumps, balances, circulators, etc.

- Atlas Reporting Software: Allows easy graphical analysis of log files generated by either the Base Unit, Atlas Software 1, or the Atlas Syringe Pump

- Atlas Parallel Software: Will control many Atlas systems (up to 4) and allow them to be connected to one PC and be controlled in parallel

- Atlas Calorimetry Software Upgrade: Used with Atlas Software 1, the Atlas Calorimetry Software Upgrade enables heat flow calorimetry and power compensation calorimetry to be performed

- Atlas COM Port Software: Provides the same functionality as Atlas Software 1, with the exception that it uses RS232 connection directly to the PC rather than via an Atlas Port

Atlas Laboratory Software 1 is an easy-to-use, PC-based application for control and analysis of experiments. Whole systems including stirrers, circulators, temperature sensors, pumps, balances, FTIR probes, FBRM, probes, etc. can be configured using virtually any manufacturer’s apparatus, by using an Atlas Port. The “drag and drop” interface means recipes can be created, changed and saved with the click of a mouse.

Atlas Software enables setpoints, ramps, or sophisticated profiles of control parameters to be set using tables or graphs. It is easy to define end conditions, shutdown limits, and alarms.

Sophisticated actions such as pH control, using a pump and pH meter, or gravimetric dosing using a balance and pump, are made easy.

During a reaction, the Atlas Laboratory Software allows responses to be continuously monitored and graphed with easy to use alarms and emergency control.

Experiments can be modified on-the-fly, and all reaction data is continuously logged to CSV data files making analysis very easy.

Watch the video or contact us for more information.