Plug flow reactor vs batch reactor

Choosing the right reactor design is a critical decision for chemical engineers and chemists, as it impacts reaction efficiency, product quality, and overall process economics.

In this blog, we’ll compare the plug flow reactor (PFR) and batch reactor, highlighting their unique characteristics, benefits, and applications. We’ll also touch on other reactor types, such as continuous stirred-tank reactors (CSTR) and continuous oscillatory baffled reactors (COBR), to provide a comprehensive understanding of continuous reactor design.

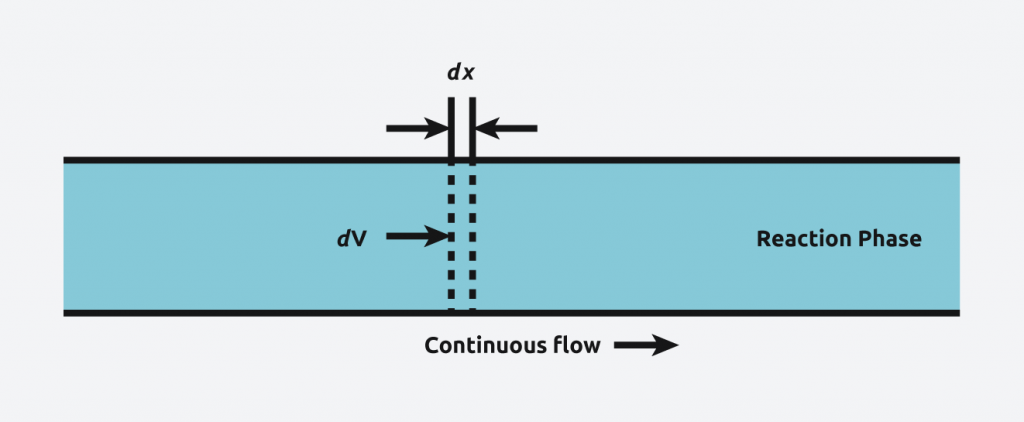

What is a plug flow reactor?

A plug flow reactor (PFR) is a type of continuous reactor where reactants flow through a cylindrical tube with minimal back-mixing. The reactants travel in a “plug-like” manner, meaning all elements move with uniform velocity, resulting in a consistent residence time across the reactor.

A plug flow reactor (PFR) is a type of continuous reactor where reactants flow through a cylindrical tube with minimal back-mixing. The reactants travel in a “plug-like” manner, meaning all elements move with uniform velocity, resulting in a consistent residence time across the reactor.

Benefits of plug flow reactors

- Efficient Conversion: PFRs often achieve higher conversion rates for first-order reactions due to their optimized plug flow characteristics.

- Thermal Management: By maintaining a steady flow and heat transfer, PFRs effectively manage thermal loading, reducing the risk of hotspots.

- Scalability: Their linear flow design simplifies scaling up for industrial applications, making them ideal for large-scale continuous processes.

- Enhanced Selectivity: For specific chemistries, PFRs can optimize reaction conditions to favour the desired product.

Plug flow reactors are particularly useful in industries like petrochemicals, pharmaceuticals, and food processing, where consistent product quality and high reaction efficiency are essential.

What is a batch reactor?

A batch reactor is a closed system where all reactants are added at the beginning, and the reaction proceeds over a defined time under controlled conditions. Once the reaction is complete, the product is removed, and the reactor is cleaned for the next batch operation.

A batch reactor is a closed system where all reactants are added at the beginning, and the reaction proceeds over a defined time under controlled conditions. Once the reaction is complete, the product is removed, and the reactor is cleaned for the next batch operation.

Benefits of batch reactors

- Flexibility: Batch reactors are well-suited for small-scale production and processes requiring frequent changes in reactants or product formulations.

- Precision control: They allow precise control over reaction time, temperature, and mixing, making them ideal for fine chemical and fragrance batch control.

- Ease of monitoring: Batch operations enable chemists to monitor reaction progress and make adjustments in real time.

- Cost-effective for small volumes: For small-scale productions or research and development, batch reactors are often more economical.

Batch reactors are commonly used in pharmaceuticals, specialty chemicals, and industries where tailored or small-batch production is required.

When to use PFR vs batch reactors

The decision to use a plug flow reactor or a batch reactor depends on the specific chemistry, process requirements, and production scale. Here are some considerations:

- Continuous production: For high-volume, continuous production with consistent quality, a PFR is often the preferred choice.

- Customised batches: For processes requiring precise control, such as fragrance batch control, batch reactors offer greater flexibility.

- Reaction time and scale: PFRs are advantageous for reactions with short residence times, while batch reactors are better for reactions needing extended reaction times.

- Thermal sensitivity: In processes where temperature control is critical, the continuous flow of a PFR can provide better thermal management compared to a batch reactor.

When comparing CSTR vs batch reactor designs, CSTRs offer steady-state operation and uniform mixing, making them ideal for liquid-phase reactions. In contrast, batch reactors excel in versatility and precise control. Comparing CSTR vs PFR vs batch, the choice depends on the balance between continuous production efficiency, residence time, and the need for batch operation flexibility.

Other Types of Reactors

Beyond PFRs and batch reactors, other reactor designs are worth considering for specific applications (see right).

- Each reactor type has its advantages and challenges, and selecting the right design requires understanding the chemical and process requirements.

1. Continuous Stirred-Tank Reactor (CSTR):

CSTRs are continuous reactors where reactants are continuously added, and products are removed simultaneously. They are ideal for reactions requiring thorough mixing and uniform conditions.

2. Continuous Oscillatory Baffled Reactor (COBR):

This innovative continuous reactor design enhances mixing and residence time distribution through oscillatory flow. COBRs are particularly suited for processes with small batch oscillatory requirements and where enhanced mixing improves reaction outcomes.

3. Hybrid Systems:

Combining elements of batch and continuous reactors, hybrid systems offer flexibility and efficiency for complex processes.

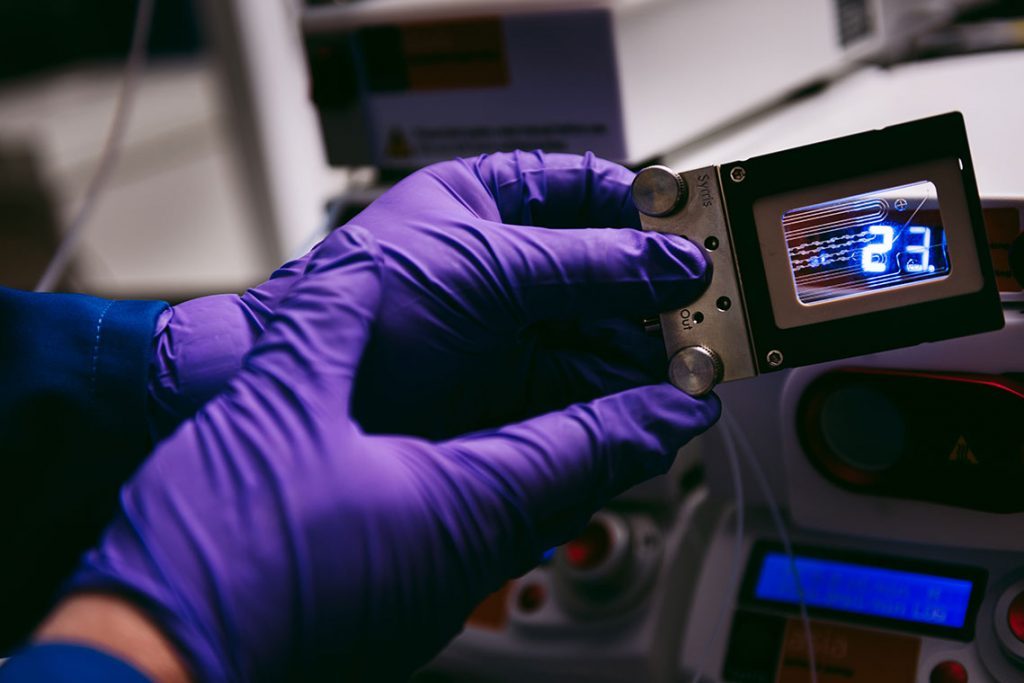

Advanced reactor solutions from Syrris

Understanding the difference between CSTR, PFR, and batch reactor designs is key to optimizing your chemical processes. At Syrris, we specialise in advanced reactor systems, including batch reactors, continuous reactors, and innovative solutions for challenging chemistries. Whether you’re managing fragrance batch control, scaling up production, or exploring continuous oscillatory baffled reactor designs, we have the expertise and technology to support your needs.

Explore our range of reactor systems and discover how we can help you achieve process benefits, improve residence times, and optimize your operations. Contact us today to discuss your requirements or request a demonstration of our cutting-edge solutions.

Contact our team of specialists to find out more about our reactor systems and how they can benefit your chemistry.

Syrris products featured in this article

Asia Flow Chemistry System