Publication – Continuous biodiesel production with continuous liquid-liquid extraction and online MS analysis

Fuel Chemistry Division Preprints 2008

Elizabeth Crawford,2 Russell Dahl,4 Douglas Duquette,1 Daniel Grant,4 Richard Gray,* Brian Musselman,2 Martin Peacock1 and James Petersen3

- Syrris Inc, 29 Albion Place, Charlestown, MA,

- IonSense Inc., 999 Broadway, Suite 404, Saugus, MA

- Amgen, 1 Amgen Center Drive, Thousand Oaks, CA

- Burnham Institute for Medical Research, Torrey Pines Road, La Jolla, CA

Abstract: Biodiesel is an alternative fuel for diesel engines that is gaining attention in the US. Its advantages are that: it is a renewable fuel; it is non-toxic and is biodegradable and can be used in diesel engines without requiring extensive engine modification.

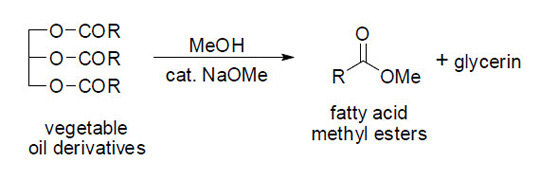

Biodiesel production involves the conversion of triglycerides into fatty acid esters, typically under Zemplén conditions. The rate limiting step in these reactors is not chemical kinetics, but mass transfer due to the immiscibility of the vegetable oil and the alcohol. The shear forces in the stirred tank reactors are not sufficient to effectively mix the two phases.

This paper was performed on the Africa system (replaced by Asia).