Publication – The use of flow chemistry for two-phase dibromocyclopropanation of alkenes

Journal of Flow Chemistry 2015

- Runa B. Østby1, Yngve H. Stenstrøm1 and Terje Didriksen

- Department of Chemistry, Biotechnology and Food Science, Norwegian University of Life Sciences, Norway

- SINTEF Materials and Chemistry, Oslo, Norway

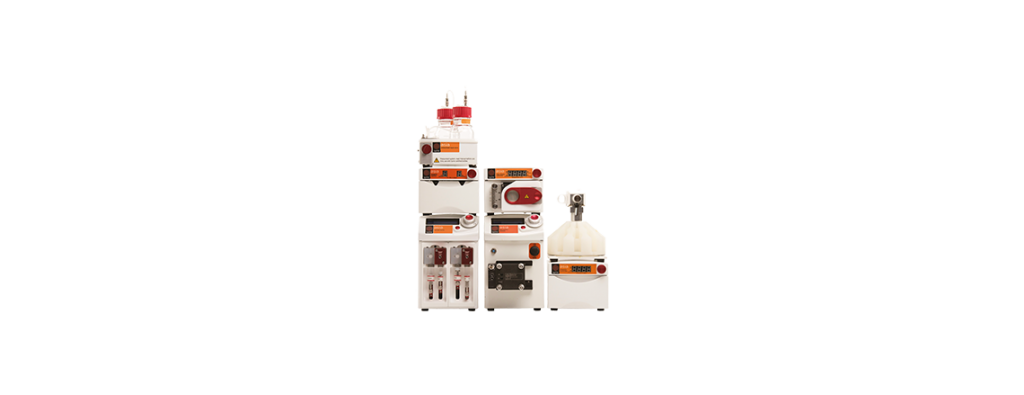

Using a Syrris flow system and glass microreactors, researchers at the Norwegian University of Life Sciences and SINTEF Materials and Chemistry have demonstrated a novel method for the dibromo-cyclopropanation of alkenes via a continuous two-phase method.

Gem-Dibromocyclopropanes are versatile intermediates in the synthesis of many natural products and are usually prepared via a two-phased catalyzed dihalocyclopropanation of alkenes.

The introduction of two immiscible phases into a microreactor generates a large specific interface area with two distinct, alternating phases. The mass transfer within a microreactor is further increased by the internal circulation within the alternating ‘slugs’. Reactions of this type carried out under flow conditions contribute not only to increased mass transfer but increased rates and better selectivity.

Using this methodology the group obtained gem-dibromo-cyclopropanes in good to excellent yields in less time than the equivalent batch reaction across a range of alkenes.

Abstract: Conventional batch dibromo-cyclopropanations by reaction of bromoform and alkenes under phase-transfer conditions require a strong base (50% NaOH (aq)), vigorous stirring, and often long reaction times. Using flow chemistry in a microreactor, the reactions were found to be smooth, rapid, and high-yielding under ambient conditions when 40% (w/w) NaOH was used as the base. The reaction has been tested with a representative selection of alkenes, displaying a variety of structural features.

This paper uses the Asia Glass Microreactor. Learn more about the product this chemistry was performed on.

For more information, contact us.