Optimize your process today with our Syrris batch reactors

Syrris offers a range of batch reactors, including the Atlas HD, Orb and Orb Pilot systems, designed to optimize laboratory and pilot-scale chemistry processes.

Our reactors provide precise control over reaction conditions, ensuring consistent and reproducible results. With modular designs, our reactors cater to various applications such as crystallization, reaction calorimetry, and process development.

Syrris batch reactors are recognized for their flexibility, ease of use, and scalability, making them ideal for researchers and engineers aiming for efficiency and innovation in chemical research.

Get in touch with a Syrris specialist to discuss your requirements.

Syrris batch reactor product range

Syrris offers a range of batch reactors, including the Atlas HD, Orb and Orb Pilot systems, designed to optimize laboratory and pilot-scale chemistry processes.

Our reactors provide precise control over reaction conditions, ensuring consistent and reproducible results. With modular designs, our reactors cater to various applications such as crystallization, reaction calorimetry, and process development. Syrris batch reactors are recognized for their flexibility, ease of use, and scalability, making them ideal for researchers and engineers aiming for efficiency and innovation in chemical research.

- Atlas HD interchangeable vessels from 50 mL to 5 L

- Orb jacketed high performance and excellent value

- Orb Pilot for scaling up of batch processes

Syrris in Numbers

Syrris works in partnership with over 50 well-trained distributors worldwide, offering expert knowledge and local support

Our customers have published over 500 publications using Syrris systems, demonstrating their viability for real-world chemistry

Thousands of chemists and chemical engineers use Syrris products in their ground-breaking research and development, including at the world’s top 20 pharmaceutical, chemical, and food and fragrance companies

Syrris batch reactor range

Modular in design, with a wide vessel range and broad temperature limits, Syrris reactors can be used in many applications, including process development and optimization, advanced synthesis, crystallization, automated synthesis, and more.

Our Customers

Syrris is proud to have a large customer base including the top 20 pharmaceutical companies, most major academic institutions, CRO’s, chemical and biotech companies in over 45 countries worldwide.

What our customers say

Our Atlas Potassium reactors, with pH control and an Atlas Syringe Pump XL, have allowed us to scaleup production, enabling variables such as pH and temperature to be tightly controlled.

Batch reactors for every stage of your process

Syrris offers a range of batch reactors, including the Atlas HD, Orb and Orb Pilot systems, designed to optimize laboratory and pilot-scale chemistry processes.

Our reactors provide precise control over reaction conditions, ensuring consistent and reproducible results. With modular designs, our reactors cater to various applications such as crystallization, reaction calorimetry, and process development. Syrris batch reactors are recognized for their flexibility, ease of use, and scalability, making them ideal for researchers and engineers aiming for efficiency and innovation in chemical research.

-

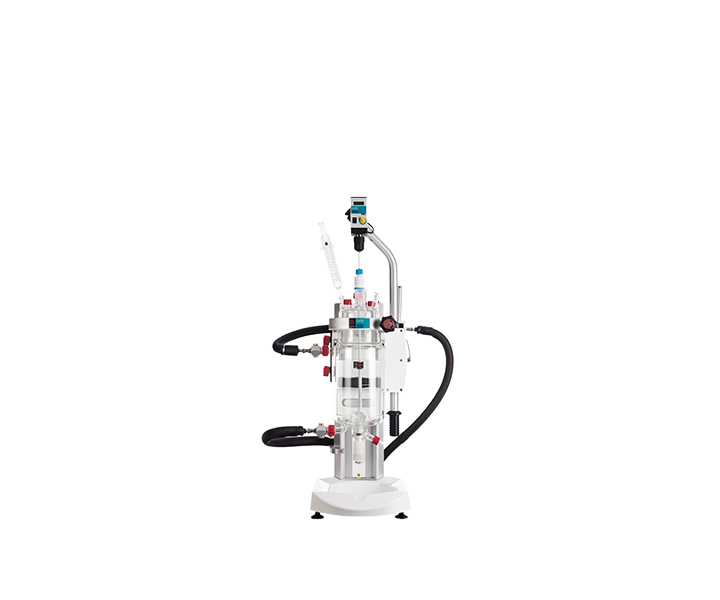

Atlas HD - the ultimate automated jacketed reactor

An automated and modular jacketed reactor platform range that offers supreme flexibility and seamless interchangeability of jacketed reactors from 50 mL to 5 L.

-

Orb - designed with simplicity and flexibility

Designed with simplicity and flexibility in mind, Orb is the jacketed reactor system combining high performance and excellent value.

-

Orb Pilot - scale up your process seamlessly

Orb Pilot is a pilot-scale modular jacketed reactor for scaling up of batch processes and offers multiple setups in one footprint.

Specifications

| Temperature Range | -100°C to +250°C |

|---|---|

| Flow Rate | 1 μL/min to 10 mL/min per pump channel |

| Residence Times | 1 second to multiple hours |

| Pressure Range | 0 to 20bar (300psi) |

| Liquid Phase Reactor Volumes | 62.5 µL, 250 µL, and 1,000 µL for glass microchips, 4 mL and 16 mL for tube reactors |

| Solid Phase Reactor Volumes | 0.7 mL, 2.4 mL, 5.6 mL, and 12 mL |

| Wetted Parts | Glass, PTFE and PCTFE (stainless steel and hastelloy possible) |

| Mixing | Rapid diffusion mixing |

| Production Volumes | Milligrams to Kilograms |