Designed by chemists for chemists, Asia enables the widest variety of chemical reactions and ultimate ease of use.

Our products are used in laboratories around the world, offering a revolutionary approach to chemical synthesis. Asia is known for innovative features like modular design for customizable setups, precise control over reaction parameters, and automation capabilities for streamlined workflows.

With a strong emphasis on safety and scalability, our systems enable efficient experimentation, optimized workflows, and enhanced productivity.

Asia systems ultimately empower chemists to achieve consistent, high-quality results while maintaining a safe working environment.

Syrris in Numbers

Syrris works in partnership with over 50 well-trained distributors worldwide, offering expert knowledge and local support

Our customers have published over 500 publications using Syrris systems, demonstrating their viability for real-world chemistry

Thousands of chemists and chemical engineers use Syrris products in their ground-breaking research and development, including at the world’s top 20 pharmaceutical, chemical, and food and fragrance companies

Asia Lab scale flow chemistry

We help chemists and chemical engineers unleash their potential by providing systems that solve their problems. From flow chemistry to nanoparticle synthesis through to crystallization and process development, we provide the best solution for your chemistry. Get in touch today to discover how the Asia System can be tailored to your application.

Asia does it all

Chemists have complete control with Asia. It makes it easy to set up and run manual or automated experiments with production scales of mg to kg and with a range of temperatures, pressures, and reaction times to suit your needs.

With all wetted materials offering maximum chemical resistance, an Asia system will give you years of continuous service.

Winner of the R&D 100 Award for innovative technology, the Asia Flow Chemistry System is a benchmark of excellence in continuous flow and is proven in over 400 publications.

-

Complete Control

Easily set up and run manual or automated experiments with production scales of mg to kg and with a range of temperatures, pressures, and reaction times to suit your needs

-

Years of continuous service

A worthwhile investment; all wetted materials on an Asia system guarantee maximum chemical resistance

-

Industry recognised excellence

Winner of the prestigious R&D 100 Award for technological innovation

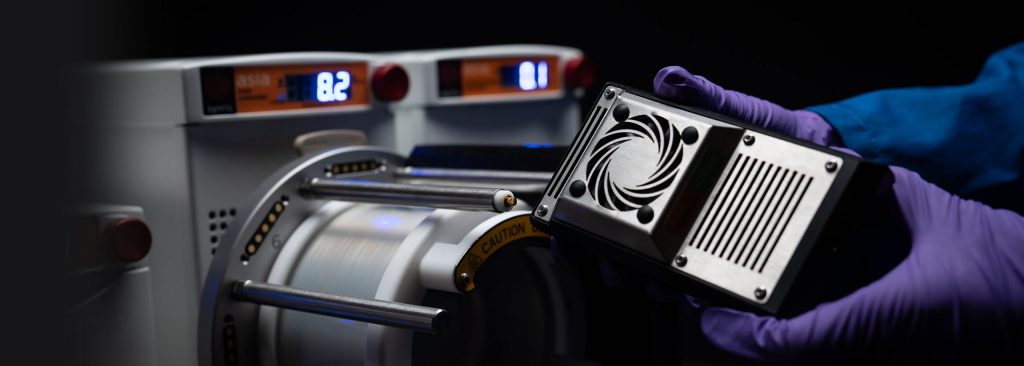

Smooth and accurate pumping

The Asia Syringe Pump is at the heart of our flow systems, providing incredibly smooth flow rates over the complete range of dynamic flow rates.

Two independent flow channels, each with an integrated pressure sensor, provide an accurate flow rate range from 1 ?L to 10 mL/min. Precise flow rates with extremely smooth pressure output are essential if you want to achieve the greatest control of your flow chemistry experiments in drug discovery.

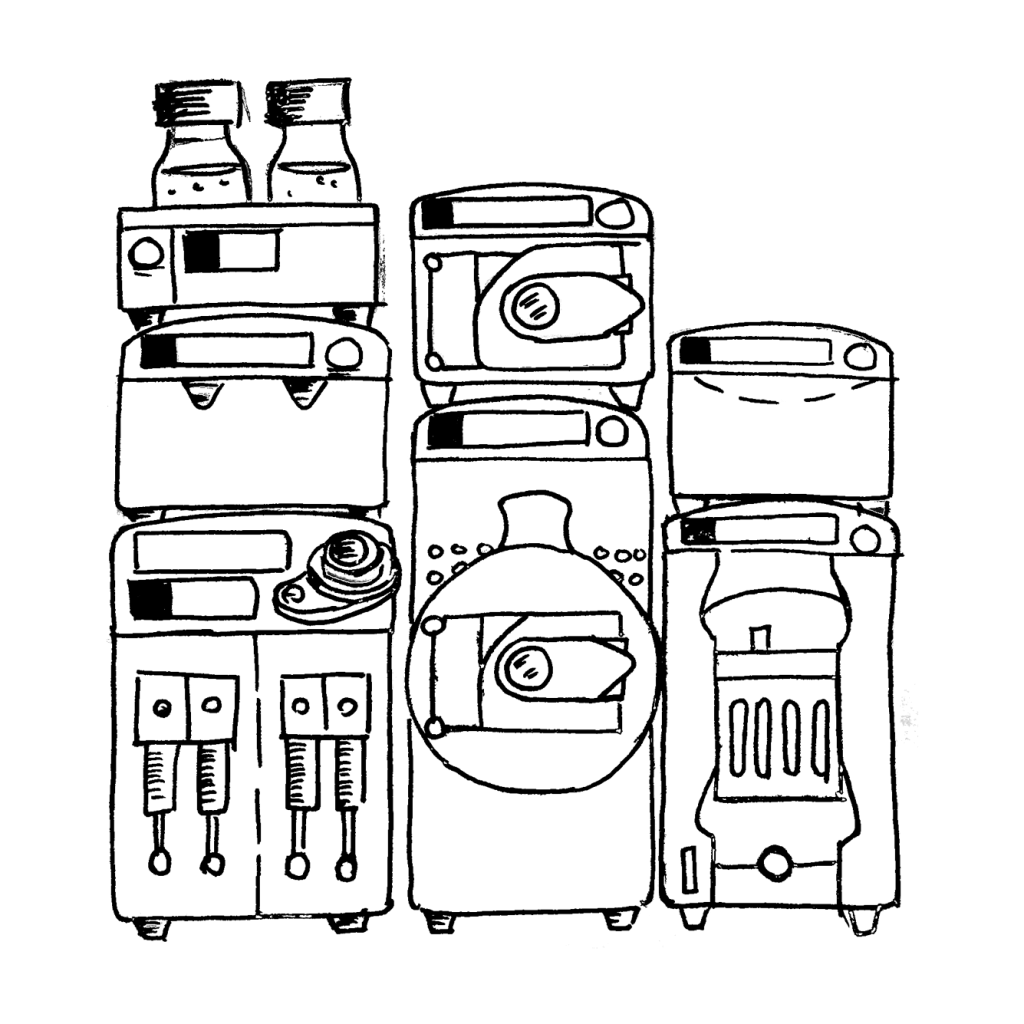

Flexible flow experiments

Asia offers a range of reactors, including glass microreactors, tube reactors, and solid phase column reactors in a range of configurations and sizes.

Optimized for heat and mass transfer, Asia reactors give you the greatest flexibility when designing your flow chemistry experiment.

Tailored to your chemistry

Asia modules are available in a variety of pre-configured systems designed to perform specific flow chemistry applications.

Whatever system you choose, you’ll never be limited in your capability to perform new flow chemistry experiments and access new chemical spaces because modules can be added to your system at any time.

All Asia modules are interchangeable, giving you the freedom to configure a system of your own. Take control of the functionality and tailor the system to suit your chemistry.

Get in touch now

Our Customers

Syrris is proud to have a large customer base including the top 20 pharmaceutical companies, most major academic institutions, CRO’s, chemical and biotech companies in over 45 countries worldwide.

What our customers say

We chose the Asia Flow Chemistry System because of its ability to provide options for multiple setups in a single platform: this level of flexibility is unique to Asia products.

Specifications

| Temperature Range | -100°C to +250°C |

|---|---|

| Flow Rate | 1 μL/min to 10 mL/min per pump channel |

| Residence Times | 1 second to multiple hours |

| Pressure Range | 0 to 20bar (300psi) |

| Liquid Phase Reactor Volumes | 62.5 µL, 250 µL, and 1,000 µL for glass microchips, 4 mL and 16 mL for tube reactors |

| Solid Phase Reactor Volumes | 0.7 mL, 2.4 mL, 5.6 mL, and 12 mL |

| Wetted Parts | Glass, PTFE and PCTFE (stainless steel and hastelloy possible) |

| Mixing | Rapid diffusion mixing |

| Production Volumes | Milligrams to Kilograms |