Why choose Syrris for your polymerization chemistry needs?

Whether you’re working with traditional batch chemistry techniques, flow chemistry techniques, or looking to perform safety and scale-up studies of your polymerization chemistry, Syrris can help.

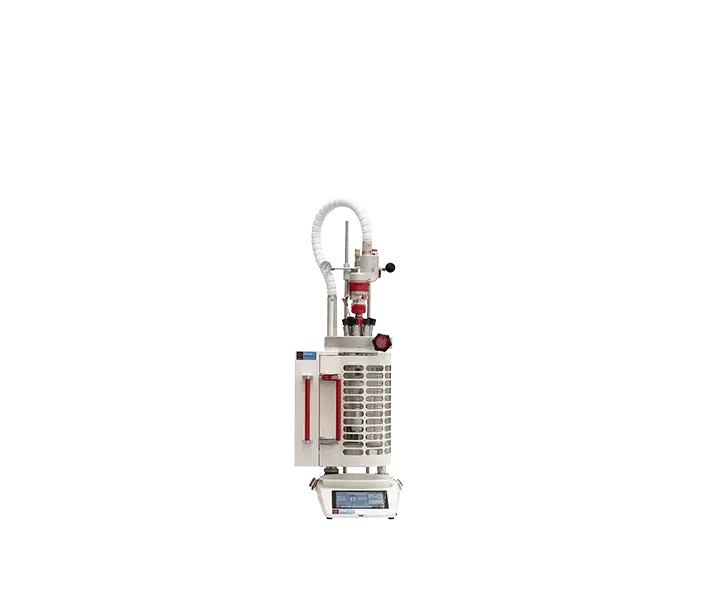

Syrris offers innovative, modular, reliable and easy to use batch reactor systems, calorimetry products, and advanced flow chemistry systems which enable precise control and automation of reaction parameters required in polymerization studies.

Polymerization using Syrris’ batch chemistry systems

Atlas HD batch reactor systems offer automation and excellent control over parameters such as temperatures, pressures, mixing, concentrations, as well as reaction times. This enables chemists to reduce the polydispersity and achieve batch to batch reproducible results.

Petroleum and Petrochemical provider PTT in Thailand invested in three Atlas 3 bar reactor systems to test their polymerization chemistry. Supabhorn Korboonsungserm, a Researcher in the Process Technology Department, explains:

We synthesize catalysts for the production of polyolefins such as polyethylene and polypropylene and test the polymerization in slurry and gas phase processes. To help with this work, we have invested in Atlas modular products, which are very adaptable and can form a wide range of chemical reactors.”

Flow chemistry systems for polymerization chemistry

Asia flow chemistry systems are ideal for achieving high control of the polymerization reaction. Key advantages of flow chemistry such as ultrafast mixing, improved temperature control, and easy scale-up benefit result in better, cleaner and more efficient polymerization reactions.